Product

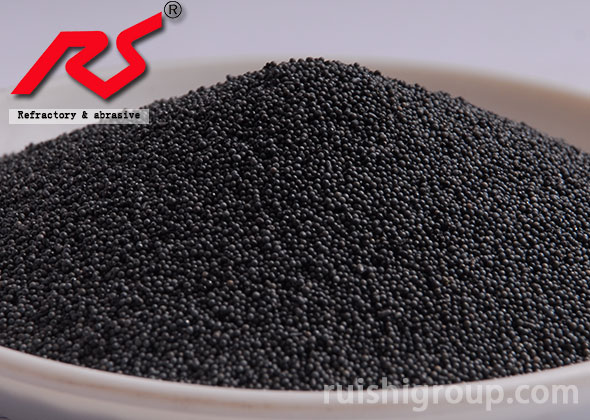

Ceramsite (Foundry sand)

Description of Ceramsite (Foundry sand)

RS Group ( Ceramic Foundry Sand Branch Plant) professionally produce Ceramic Foundry Sand. It also named ( Ceramsite, Fused Ceramic, Ceramic Sand), which is fused in the electric Furnace with high quality bauxite as the raw material. Our Capacity is 18000MT per year. Ceramic Foundry Sand is widely used in various casting ways ( investment casting, full mold casting, lost foam casting and so on ); It is a new type casting sand used in precision casting, resin coated sand,self-hardening sand. In particular, it has the characteristic of low expansion sintering, no pulverization, no cracking, no sand sticking (to eliminate the negative impact of casting quality), good regeneration performance, and improve the casting yield.

Application of Ceramsite (Foundry sand):

1、Widely used in foundry technique like resin-bonded sand, sodium silicate sand, and clay- bonded sand for sand core and casting mould making.

2、Replace chromite sand and widely used in sand core making like jacket core, oil duct core, tappet core of engine.

3、Replace chromite sand for steel casting facing sand and sub-layer of molding sand (backing sand).

4、Widely used as dry sand and sand box for EPC process and V method of casting processes.

5、Widely used as the main raw materials of advanced refractory products (Ladle drainage sand,gravity casting material, casting coating, etc.).

6、Widely used as cleaning sand for copper and aluminum alloy castings.

Advantage of Ceramic foundry sand:

1、Perfectly round shape with higher fluidity improves fill-in efficiency while reducing the resin leve

2、Smooth surface of spherical shape greatly improves collapsibility after pouring

3、Very low thermal expansion ensures fewer or no casting defects such as veining and deformation

4、Excellent thermal conductivity and heat absorption capacity close to that of Zircon

5、Superior refractory equivalent to Zircon and Chromites

Specification:

Ceramic foundry sand for casting and precision casting

|

Purpose |

Specification |

Chemical composition(%) |

Bulk Density : |

||

|

Al2O3 |

Fe2O3 |

Na2O+K2O |

|||

|

Casting |

AFS20-AFS120 |

70-75% |

5.0% Max |

1.0% |

|

|

75%min |

2.5% Max |

K2O:0.50%max |

|||

|

specification |

mesh |

10 |

14 |

18 |

26 |

36 |

50 |

70 |

100 |

140 |

200 |

281 |

Pan |

|

|

um |

1700 |

1180 |

850 |

600 |

425 |

300 |

212 |

150 |

106 |

75 |

53 |

Pan |

|

|

|

AFS:20 |

|

≤5 |

10-30 |

30-50 |

15-35 |

≤5 |

|

|

|

|

|

|

|

|

|

AFS:30 |

|

|

≤6 |

10-20 |

30-50 |

15-35 |

≤10 |

≤5 |

|

|

|

|

25-35 |

|

|

AFS:40 |

|

|

|

≤5 |

0-20 |

20-40 |

20-40 |

10-30 |

≤10 |

≤2 |

|

|

30-55 |

|

|

AFS:50 |

|

|

|

≤3 |

≤15 |

25-40 |

25-40 |

10-20 |

≤10 |

≤5 |

≤3 |

|

45-55 |

|

|

AFS:60 |

|

|

|

|

≤10 |

10-30 |

30-50 |

15-25 |

0-20 |

≤5 |

|

|

55-65 |

|

|

AFS:75 |

|

|

|

|

|

≤10 |

5-25 |

25-45 |

20-40 |

≤10 |

≤5 |

|

75-85 |

|

|

AFS:100 |

|

|

|

|

|

|

≤3 |

10-30 |

35-55 |

15-35 |

≤10 |

≤2 |

105-115 |

|

|

AFS:125 |

|

|

|

|

|

|

≤2 |

0-20 |

30-50 |

25-45 |

0-20 |

≤5 |

125-135 |

|

|

AFS:150 |

|

|

|

|

|

|

|

≤5 |

5-25 |

40-60 |

25-40 |

≤15 |

160-170 |

|

Particle size :AFS 20-AFS120

Packing: 1 MT big bag or 25kg paper bag *40 bags on one pallet ;As per customer’s requirement

Remark:

specification and size can be optimized by per customer' requirement

COA:Please click the picture to view the big picture

give your inquiry in below.

give your inquiry in below.